Industry

The Different Types of Masonry Anchor Bolts

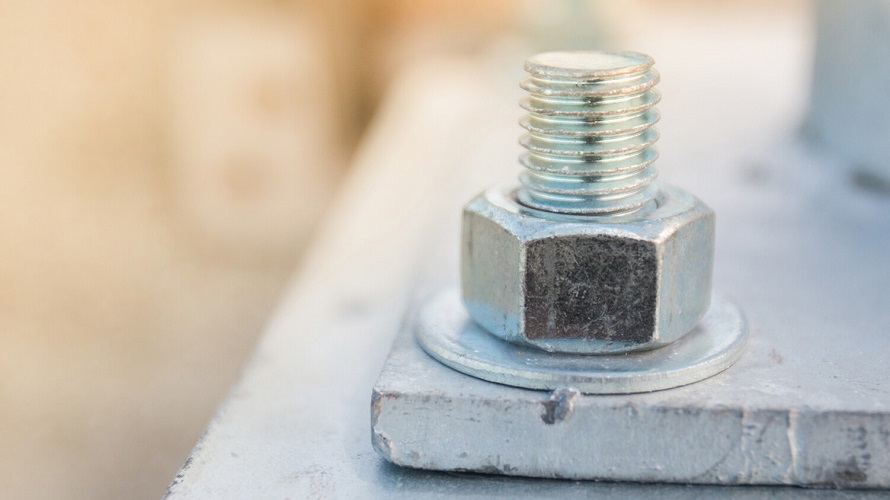

Masonry is one of the most widespread building methods today. It involves using bricks, stone, or concrete, bound together by mortar, to build a variety of structures like bridges, houses or office and residential buildings. Different items like handles, beams, support columns, poles and gutters can be affixed to masonry by way of masonry anchors, or fixings like bolts, fasteners and screws, to provide durable, lasting connection.

Types of Masonry Anchor Bolts

There are different categorisations of masonry anchor bolts, the most common being when the bolts are installed during the construction process. In this sense, there are two major types – cast-in-place anchor bolts and post-installed anchor bolts. Both consist of several bolt types, something I’ll discuss below.

Cast-in-Place Anchor Bolts

Cast-in-place bolts are the simplest types of masonry bolts and are affixed during construction. They are mainly used in concrete structures and are applied when the concrete is still wet. They require careful planning in terms of where they are placed, since this may affect structural stability. When used correctly, they provide high tensile strength in structures with high weight loading. There are several types of bolts used:

Headed Anchor Bolts

Headed masonry anchor bolts are the most common cast-in anchors. They have either a hexagonal or square head, a threaded midsection and a tapered end or chamfer. Headed anchors are mainly used in connecting structural elements in concrete because of their high tensile strength. They are sold in different diameters and lengths.

Bent Bar Anchor Bolts

Bent bar masonry anchors come in different shapes, the most commonly used being the ‘L’ and ‘J’ shaped anchors. Bent bar bolts are used to fix embed plates and columns into concrete. Other bent bar bolts include ‘U’ bolts used in attaching such things as signs, and eyebolts – used for creating secure attachment points.

Through Bolts

Through bolts consist of rods that go through the entire width of the masonry and are affixed by plates at the surface. They’re typically used in industrial construction.

Post-Installed Anchor Bolts

Post-installed anchor bolts are used at the end of the construction process, typically in solid brick structures. There are two major types – expansion anchor bolts and chemical anchor bolts. Expansion bolts are installed in drilled holes in the masonry. They expand into the masonry material once tightened at the required torque. There are two main types:

Sleeve Anchor Bolts

Sleeve anchors have a metal sleeve or shield which expands into the masonry when the bolt is tightened. They are the most commonly used anchor bolts in brick structures. They are used in such instances as connecting light fixtures to ceilings, attaching doors or radiators to walls, or securing junction boxes.

Wedge Anchor Bolts

Wedge anchor bolts are used in pre-drilled holes along with wedge drop-in or lipped drop-in sleeves. The wedges expand in the base material when the bolt is tightened. Wedge anchor bolts are used in affixing items to concrete, mainly in industrial settings. Common uses include setting window frames, heavy-duty shelving or machinery into concrete walls.

Chemical Anchors

Chemical anchors are created by the use of adhesive, usually epoxy, along with ribbed or threaded studs. Injection tools are used to inject the epoxy in the drilled hole where the stud, along with the washer and tightened nut are placed. On curing, the epoxy hardens, filling in any voids in the base material. Chemical anchors are used along the edges of the material where the expanding forces of expansion bolts might cause crumbling or cracks. Chemical anchors, including studs, epoxy and different capsules, are newer solutions that need a little more attention to get right. They are also generally more expensive than expansion anchors, but provide greater flexibility in terms of anchor depth. Common uses of chemical anchors include door handles and rails.

These are the main types of bolts and anchoring solutions used in masonry. Others include masonry screws used in light concrete applications, frame plugs for attaching heavy wooden items, or drive pins used in attaching objects like metal brackets.

What to Consider When Buying Masonry Anchor Bolts

With so many types of bolts, screws, studs and rods used in anchoring, the first thing to consider when buying is the application. Does the product correspond to the job at hand? Though different types of anchor bolts can be used in similar projects, specialised bolts and screws are better suited in particular situations.

Some anchor bolts will be suited only for concrete, others for brickwork. Consider the fixture size and where it is fitted on the masonry. Anchor bolts in different sizes will be used in different applications. Consulting the manufacturer or retailers will clear any uncertainties as to what is suitable.

When used in masonry anchors, bolts need the required tensile strength. This is shown in tensile ratings or ‘grades’. Bolts come in different grades of steel. Lower grades are suitable for light applications in either brick or concrete, whereas treated steel alloys in higher grades are suitable for heavy-duty industrial applications where bolts need to withstand higher weight loadings. Stainless steel is the preferred material for outdoor applications since it is resistant to corrosion. For electrical applications look for anchor bolts with high resistance to galvanic corrosion.

Masonry anchor bolts and accessories, along with tools for installation, are sold in general and construction hardware stores throughout Australia.