Lifestyle

Everything You Need to Know about Lathe Machines

Few woodworking tools offer the all-around versatility a lathe does. Known as the ‘mother of machining tools’, lathes can be used for shaping, sanding, drilling, boring, threading, knurling, turning, cutting, and getting (almost) any piece of wood to the desired shape. They’re particularly useful in crafting wood pieces into rounded or cylindrical profiles. What you produce is limited only by imagination and your woodworking skills.

Everyday items made with a wood lathe include furniture legs and spindles, lamp posts, wooden boxes and containers, wooden frames, bowls, baseball and cricket bats, kitchen utensils and intricate wood objects like chess pieces, clocks, pens, musical instruments and candle holders.

Parts of a Wood Lathe and How It Works

A lathe is also called a wood-turning machine, and the piece of wood is shaped using different tools while being fixed and turned on the lathe. The primary purpose is to remove unwanted pieces of wood until the wood blank is shaped into the desired item. To understand how this is done, we must first get acquainted with the different lathe machine parts.

The main parts of a woodworking lathe are the bed, headstock, tailstock, spindles, tool rest and motor.

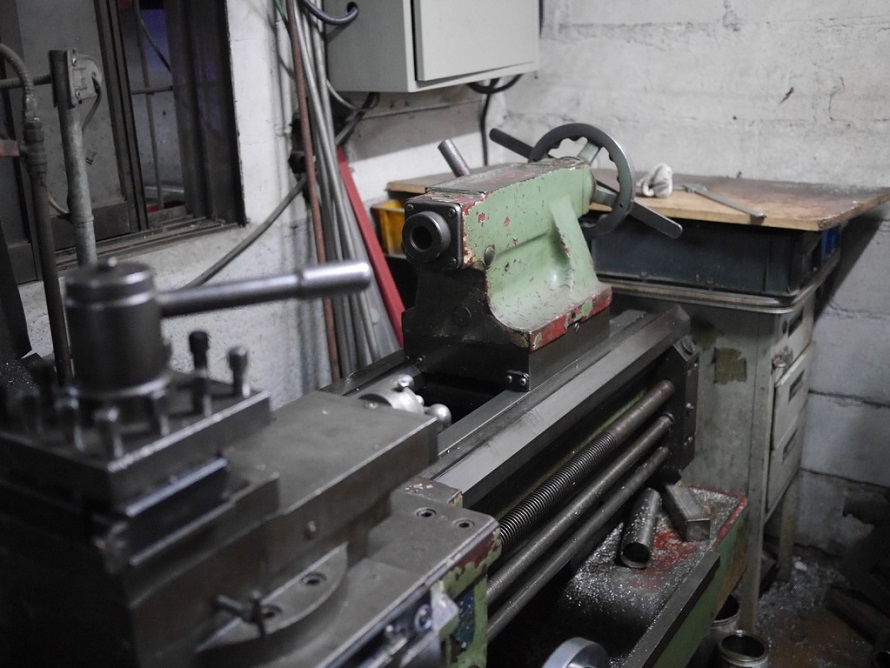

• Lathe bed – This forms the basis of the machine and has bed ways that hold and align all the separate components together. Most are made of machined cast iron or steel, but traditional lathes have beds made of wood. The size of the bed determines the overall size or diameter of the wood blank that can be worked on.

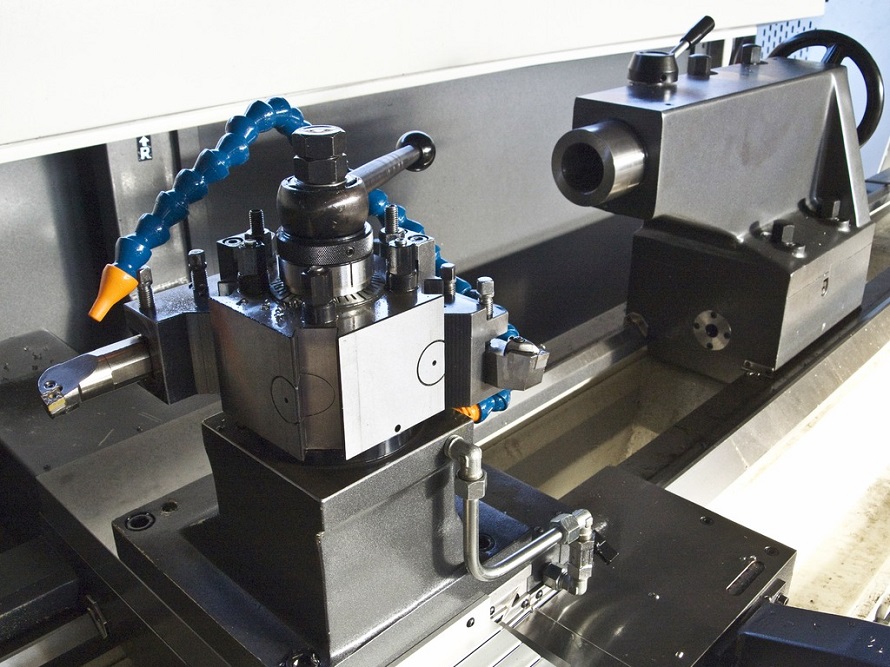

• Headstock and Tailstock – The headstock and tailstock consist of different parts that hold the wood in place. The headstock is on the left, and the tailstock is on the right. The headstock houses the spindle which rotates the workpiece as it is being shaped. It’s also where you’ll find the feed gears and spindle speed selector to vary the speed of rotation. The tailstock is used for holding various machining tools used in operations like drilling, reaming and tapping. It can be moved along the bed ways to accommodate differently sized wood blanks or removed altogether.

• Motor- This is on the underside of the bed, and under the headstock. It supplies power to turn the spindle. Most motors are electric and come in different variants (AC, DC, fixed or variable speeds and direct drive). Some lathe machines may have a hydraulic motor.

• Tool rest – Tool rests are adjustable for height and rotation. Their main purpose is to support and act as a guide for different turning and cutting tools such as bowl gouges and scrapers.

• Spindles – The rotating main spindle holds the workpiece and is hollow and threaded on the outside to fit a range of different lathe accessories such as chucks and faceplates used to position and hold the workpiece.

Shaping the workpiece is done in a few basic steps. The wood blank is placed between the headstock and tailstock and attached to the lathe machine with a chuck that keeps it stable while being rotated around its axis by the spindle. A cutting or forming tool is placed in the tool rest at an appropriate distance from the workpiece. The machine turns on with the motor starter button and the speed and direction of the spindle are controlled with a lever. For general safety, any needed adjustments are made with the motor and machine off.

Types of Lathes

By Size

Lathes come in different sizes. The distance between the headstock and tailstock centres (DBC), determines the length of the wood blank, whereas the height from the bed to the centre of the spindle, or the swing over bed (SOB), impacts the overall diameter of the workpiece. In this sense, there are three basic types of lathe machines – pen, midi and full-sized lathes.

Pen lathes are small and compact and used to carve and shape intricate wood pieces like pens, chess pieces and small wooden ornaments. This lathe machine has a DBC of 500mm or less and an SOB of no more than 300mm. Midi lathes are slightly bigger, with a DBC of around 600mm, and an SOB of 500mm and are commonly used in everyday carpentry such as shaping table and chairs legs or staircase spindles.

Where they differ from smaller pen lathes are the more powerful motors, tougher build and ability to accommodate a range of cutting and shaping tool accessories. Full-sized lathes are what you’d find in professional woodworking workshops, with a DBC of 1000mm or more and an SOB of 400mm and upwards. They can shape wood into almost any desired object but require considerable skill to operate.

By Function

The type of jobs they do, and how the wood blank is oriented when worked on is another way of classifying lathe machines. The most common type in this respect is the centre wood lathe, often having a geared transmission to accurately adjust spindle speeds and main shafts placed horizontally, so is also known as a horizontal lathe. A vertical wood lathe shapes the wood blank in a vertical orientation, good for turning wood pieces with a larger diameter. Hexagonal or turret lathes replace the tailstock of regular lathes with a hexagonal rotating turret. This is used in the mass production of wooden objects that also require drilling or boring. The most technologically advanced are CNC variants used for precision and high detail in complex objects.

Factors When Choosing a Lathe

Size and weight will impact what the lathe can be used for and where. Determine what you will be producing with the lathe and where it will be placed. Ensure that the machine has a solid build, with a cast iron base and bed to minimise vibrations and increase accuracy. While wood lathes have less powerful motors than those used in metalworking, you’d still want enough power for complex projects involving heavy wood blanks. Larger full-sized have motors exceeding 2.5 kW, while averages of 1.5 kW are enough for most DIY jobs.

Using the lathe safely also means it will have the necessary safety provisions, such as emergency and auto-off switches. And lastly, to have the versatility to shape and produce a range of different wooden items, consider things like DBC and SOB and stock up on woodturning tool basics such as chisels, gouges, scrapers, hollowing and boring tools and cutters.