Automotive

Engine Maintenance Tips to Keep Your Vehicle in Good Shape

Cars are put through much stress regularly. And every moving part is subject to wear whatever its original service life may be. This is true for the wheels, the brakes, and applies to the engine as well.

If you are one of the typical 4×4 enthusiasts then you probably have your eye on the next upgrade to protect your chassis for off-road driving. These types of upgrades, and off-road accessories in general, serve to make the driving experience more enjoyable. However vital parts need to rank high on the priority list as well. Taking proper care of the engine is a must for any mechanical failure will leave you bogged down in the hinterland.

It can be done – study your systems and do regular maintenance.

Servicing Conrods

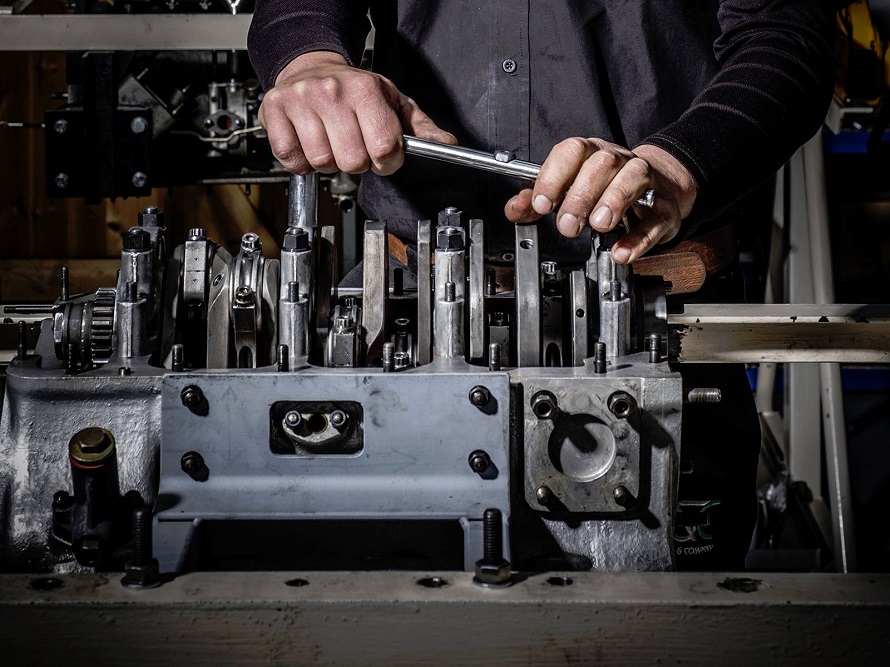

Failure of a connecting rod can damage an engine beyond repair. If the rod drives through the side of the crankcase, there is not much a mechanic can do to fix the issue. Engine rods are subject to three repetitive sources of wear – shear, compression, and tensile forces. They are all due to the movement of the piston in tune with the engine speed.

But what does a connecting rod do in an engine? It’s practically the part that connects the piston with the crankshaft. The piston moves up and down, while the crankshaft rotates. Your conrod(s) transmit the force of the piston and because the process is cyclical they rotate at both ends.

Strong performance engine connecting rods will increase the overall strength of the engine. It’s an essential part of internal combustion engines that is best when made from forged steel rods (4340 steel). This is ultimately better than the original equipment manufacturer rods found in your engine. The reason being, two-piece chrome-moly steel forging is superior and results in grain flow of the rod. Such part will handle the constant push and pull with much more grace. So rods made using the rolling forge die method are better than those your vehicle is fitted with. High-end engine connecting rods go through CNC machining in the final stages of manufacturing.

Connecting rod failure can happen due to many causes. One is high engine speeds, a valve train problem, lubrication issue, or incorrect installation. Therefore make sure you not only get strong engine connecting rods but that they are also installed properly.

Performance Air Filter

Internal combustion engines usually operate in a four-stroke cycle: intake, compression, power, and exhaust. The chamber is isolated during the phases in the second and third phases of combustion. In the first phase, air is sucked into the chamber and after the explosion, the exhaust gases are released back to the environment. The fact that the quality of air affects the fuel economy should not come as a surprise.

There is more than one way to improve the quality of air that gets into the chamber. The amount of air that can be sucked into the engine is limited and remains the same, but its temperature, pressure, and composition can be changed. Installing a forced induction system would introduce high-pressure air into the combustion chamber. They use mechanical means to achieve this and based on that there are turbochargers or superchargers.

You can also put a cold air intake filter to work. The low temperature will be beneficial to the burning of fuel and overall engine wear. Another good option is to go for an aftermarket high-flow air filter. This type of filter replacement will improve the fuel economy. You can even hear the difference when the engine is purring. These days they make them washable too. So once the membrane gets inundated with all sorts of particles you can simply wash it instead of getting a new one. The style of washable cotton will allow you long service life relative to the stock air filters. Having a good and clean membrane translates into increased airflow into the engine. This is good for the whole system. The high-flow air filter is worthwhile in the long run.

Acceleration Boost

Now with all that engine talk behind, you might want to stray away to different types of auto components and parts. But before you go from vital aftermarket parts to the likes of brake systems and wheel axles, you can keep your focus on slightly more light acceleration accessories.

There are ways to improve engine performance without making a major upgrade. It has to do with a little tweak of the throttle lag installed in your car. When you depress the pedal, a buffer called throttle lag sort of delays the command, and your engine responds only after this lag has been employed.

This aftermarket gadget, also known as the throttle control module, will allow you to experience an unimpeded reaction to your pedal work. Because of all this, you should test the accelerator on an empty road before you get the hang of it. It’s an acceleration unlike you’ve seen before.

The installation of the throttle control module takes minutes, but the effects are long-term. That is if you choose them to be. There are several modes and you can choose the appropriate at the touch of the button. Or if you don’t want to bother with any of that, you can switch to automatic mode of throttle control and just play it by ear.

Such contraptions solve issues with starting the car and are great for off-road driving. Especially along technical routes or for starting from a significant incline. Compared to the other auto parts on this list, the throttle controller is very convenient, because it changes your driving experience without investing in big undertakings.